Articles

Conserving the most flexible feed

Well-made, high-quality grass silage is one of the most valuable feeds available to farmers. It is high in energy and protein, and as a stored feed it can be one of the most flexible feeds in the farmer's toolbox to fill summer feed deficits. Conserving high-quality pasture silage during feed surplus periods is a crucial skill in pasture management. We see a huge variation in the quality of grass silage made each season, but some farmers can get it right most seasons, when others struggle. So, what management factors help ensure good quality pasture silage is harvested?

Identify pasture surplus early

There are a variety of ways for early identification of a pasture surplus on farm.

Your pre grazing covers are higher than your target.

2.8 cows/ha * 18 kgDM/cow * 25 day rotation + 1,500 kgDM/ha residual = 2,760kgDM/ha

In this example when you see pre grazing pasture cover going above 2,760kgDM/ha you have an option to remove these paddocks from the rotation.

Your pasture growth rates are greater than your pasture demand.

2.8 cows/ha * 18 kgDM/cow = 50 kgDM/d growth rate

In this example if you are measuring pasture growth rates above 50 kgDM/d then you can start to look at removing paddocks from the grazing rotation.

Your average pasture cover is greater than your target.

From the example above, if your pre-grazing trigger level is 2,760kgDM/ha and your post grazing target is 1,500 kgDM/ha, when your average pasture cover exceeds the mid-point (2,130 kgDM/ha) you can start to look at removing paddocks from the rotation.

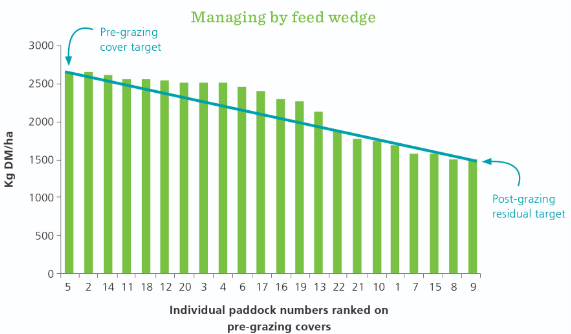

Your feed wedge identifies paddocks above the line.

If you are doing regular pasture walks the feed wedge can illustrate an emerging surplus (Figure 1). This early identification will give you some lead time to communicate with your contractor and book in advance.

Figure 1. Pasture feed wedge

Communicate

Communicate early with your contractor so that they have an idea of when you are likely to need your surplus harvested. You want to be first in the queue to reduce the risk of delays as demand for contractors increase. Let them know your needs and expectations.

Harvest

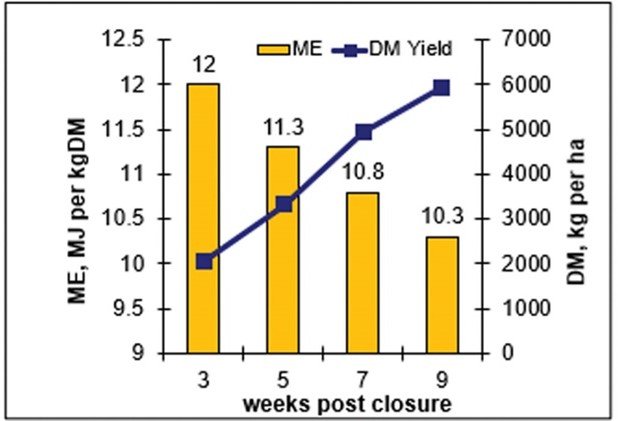

Ensure that the grass is cut while quality is still high. Many farmers make the mistake of going for quantity over quality. Silage needs to be harvested at the right time to optimise quality and quantity, ideally no later than 42 days after the last grazing (Figure 2).

Figure 2. Pasture quantity vs quality (from McGrath et al, 1998)

Ideally harvest after 2-3 days of fine weather and once harvested wilt to at least 30 percent dry matter. This concentrates the plant sugars and reduces the risk of nutrients being lost from the silage stack as run-off. Use the “Squeeze Test” to determine ideal chop length. Grab a handful of chopped grass and squeeze hard. If moisture runs out, chop the silage longer. If your hand remains dry, chop it shorter.

Store

Pasture silage can be challenging to ensile. It has a higher buffering capacity which means more acid is required to reduce the pH. Adding a quality silage inoculant like Pioneer® brand 1127 assists with a fast, efficient fermentation and minimises energy and protein losses during ensiling. Quality inoculants come from reputable companies, have label claims as to the number of live bacteria, are backed up by trial data and are supported by those people selling them.

You want to get the air out of the stack as quickly as possible. This ensures that the bacteria in the inoculant get to work straight away and produce as much lactic acid as possible. High quality silage is always compacted and sealed correctly. For stacked silage, spread material into 100 - 150mm layers and compact until the surface is firm. Use a high-quality plastic cover and weigh it down with tyres that are touching. Seal the edges with sand or lime.

The importance of a high-quality pasture silage cannot be overstated. It is a fantastic farm systems feed that is valuable for increasing milk production and complimentary to other feeds such as maize silage. In contrast, poor-quality silage is an expensive filler for dry cows. The difference in quality is largely up to things most farmers can control.

Author, Wade Bell, Pioneer Farm Systems Manager. Published by Dairy News 04/09/2024.