Technical Hub

Harvesting a maize silage crop

The timing of maize harvest and harvest management factors such as chop length and compaction have a major impact on the quality and quantity of the resultant silage.

Contractors

It is important to coordinate with your contractor prior to harvest time to ensure a timely harvest. It also pays to clarify who will be providing silage supplies (such as covers, silage tape and Pioneer® brand inoculant). Check that there is good access from the crop to the stack.

Timing of harvest

The ideal time to harvest your maize silage crop is when the whole plant drymatter is between 30 - 38%. Harvesting a crop too early will result in a yield sacrifice and a higher chance of silage run-off and a poor quality fermentation. Late harvest can result in a loss of quality as plant stover (leaf and stalk) increase in fibre and become less digestible. Dry crops are also difficult to compact properly.

In a crop that is still green (i.e. not frosted or drought stressed), the first sign that harvest is approaching is the husk covers turn slightly yellow-brown. There are several ways in which you can determine when your crop is between 30-38% whole plant drymatter. Please note that the following guidelines should only be used to determine if the crop is ready to harvest not for trading purposes.

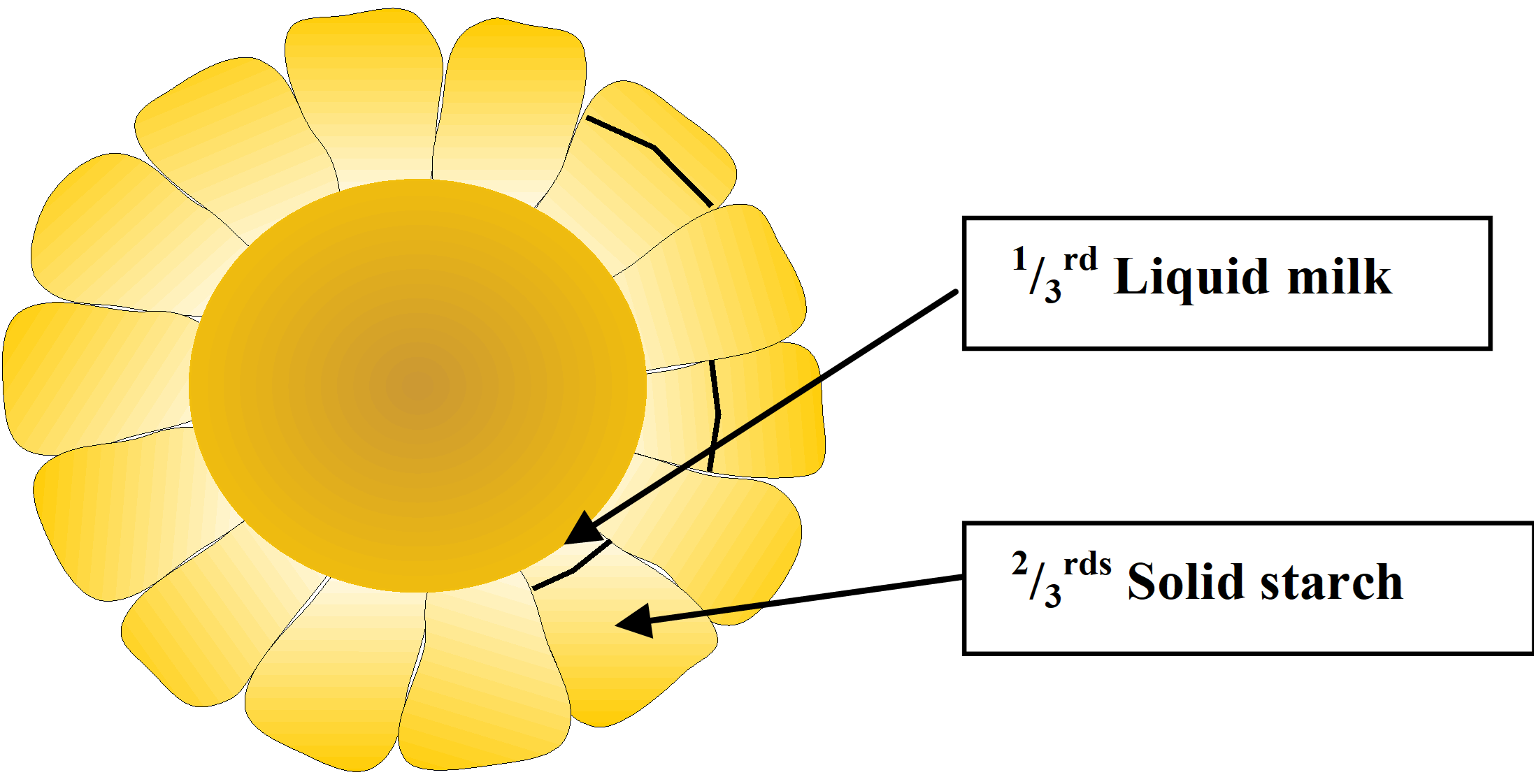

1. Milk line

The whole plant drymatter can be estimated by looking at the milk line of the grain. To check whether your crop is in the range of 30 - 38% drymatter:

- Take a cob from a plant that is at least 20 rows into the crop. The plant that you take the cob from must be in a uniformly planted row.

- Break / snap the cob in half and discard the end of the cob that was attached to the plant.

- Hold the point of the cob downwards and remove a kernel from the "snapped" end.

- Keep the kernel the same way up as when you removed it from the cob. Slide your fingernail along the length of the kernel starting at the flat (dented) end of the kernel.

- Note the point where the solid starch ends, and the liquid milk begins. The hybrid will be ready for harvest when the milk line is two thirds of the way down the kernel (see Fig 1).

- The milk line test is only indicative that harvest time is near. The only sure way to test plant drymatter is though the microwave test or by sending a plant to a suitable laboratory (see more information below).

2. Plant moisture

The moisture content in the plant (leaves and stem) can vary widely. A drought stressed crop may have all leaves up to the cob browned out and no moisture in the stem. In such situations the drymatter percentage of the crop can be higher than the milk line indicates.

3. Microwave drymatter test

Information on measuring the drymatter content of maize silage is available here: https://www.dpi.nsw.gov.au/__data/assets/pdf_file/0007/229291/silage-note-7-measuring-the-dry-matter-content-of-forages.pdf

4. Laboratory analysis

Commercial laboratories can measure the drymatter content of chopped whole plant maize samples. Some can also handle whole plants. It will take at least three days for your samples to be processed and often considerably longer. Remember that the result of a drymatter test will only be accurate if a good representative sample is submitted.

There is a Code of Practice for the Trading of Maize Forage available free of charge from the Foundation for Arable Research, PO Box 80, Lincoln 7640, or telephone 03 325 6353, or by visiting their website: www.far.org.nz. This document outlines weighing as well as drymatter testing requirements for trading crops.

Harvesting

Inform your contractor once you have determined that your crop is close to harvest. Make sure that you organise all the machinery, labour and supplies (e.g. cover, Pioneer® brand inoculant and tape) that will be required if these are not supplied by the contractor.

Chop length

The ideal chop length is 10 - 15 mm. This is a theoretical chop length and you will find some particles that are shorter or longer in your silage. Some longer particles are beneficial as they stimulate the rumen of the animal that is being fed. If your silage is very dry (greater than 38% drymatter), decrease the chop length to 5-9 mm. In the case of very wet crops (less than 30% drymatter) chop length may be increased up to 20 mm.

A good method of testing whether the chop length that you are using is correct for the moisture level is to take a handful of the harvested maize and squeeze it. The palm of your hand should feel moist. If you can wring water out of the material, you are almost certain to have run-off from your silage stack. Either increase the chop length or delay the harvest. On the other hand, if the maize silage does not stay compressed after squeezing, the maize is too dry. Chop length should be shortened.

Kernel Processing

Use a kernel processor to ensure that 99% (target minimum 80%) of the kernels are broken into at least four pieces.

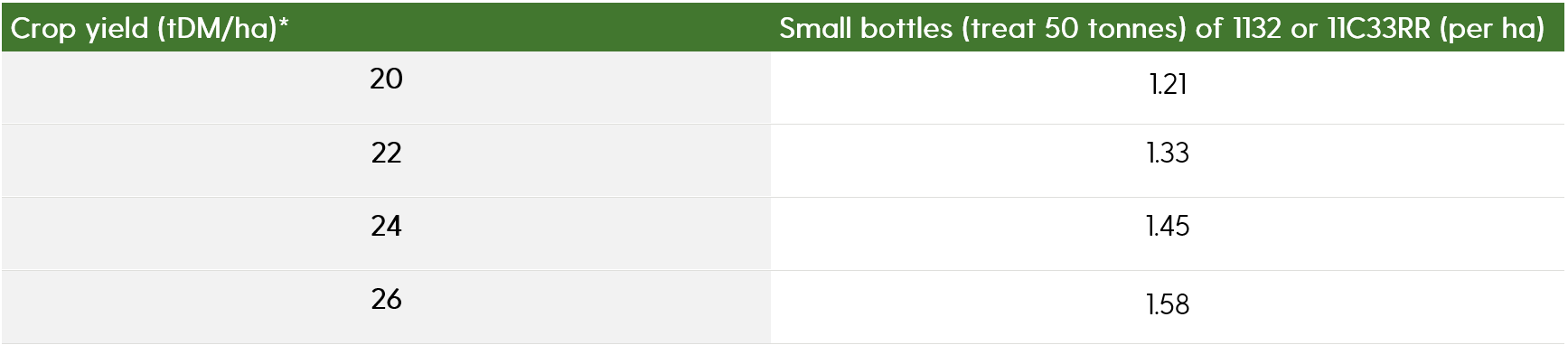

Use a proven, Pioneer® brand silage inoculant. Silage inoculants are normally applied through the forage harvester as the crop is harvested. They contain beneficial bacteria which enhance silage fermentation and/or reduce heating and drymatter loss at feed out time. As a result, you get more milk or meat per tonne of forage ensiled.

*Inoculant is applied on a wet tonne basis. Wet tonnes = dry tonnes divided by the drymatter content. In this table we have assumed that the drymatter percentage is 33%.

For more information on the Pioneer® brand inoculant range see https://www.pioneer.co.nz/product-range/inoculants/maize-inoculants

For more information call Pioneer on 0800 PIONEER (746 633) or visit www.pioneer.nz